References

Industry

Terhalle

Education

NOA Professional Education

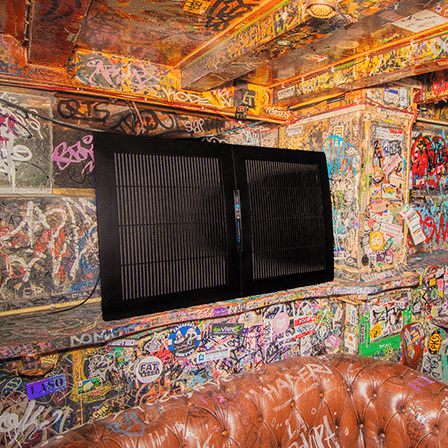

Restaurants

Hill Street Blues

Industry

Leunissen Interieurbouw

Industry

DS Smith

Industry

Klingele Paper & Packaging Germany

Industry

Woodworking Industry Fransen

Education