DS Smith is one of the world’s leading producers of (corrugated) board packaging, an innovative paper manufacturer and Europe’s largest board and paper recycler. DS Smith has clients from each size in every conceivable industry. The head office is situated in London. The company is present in 34 countries and has about 30,000 employees.

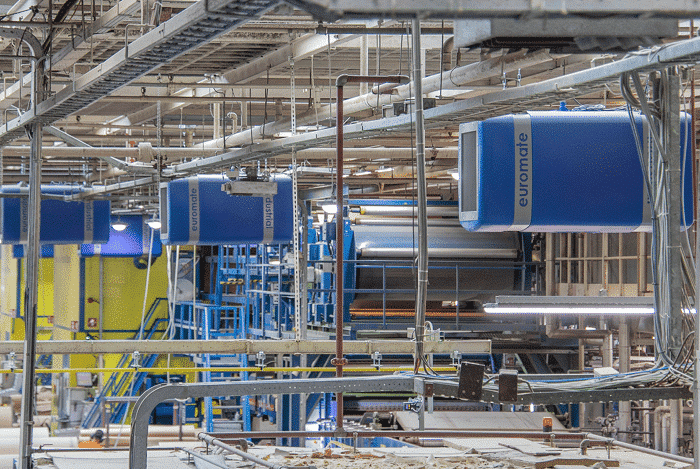

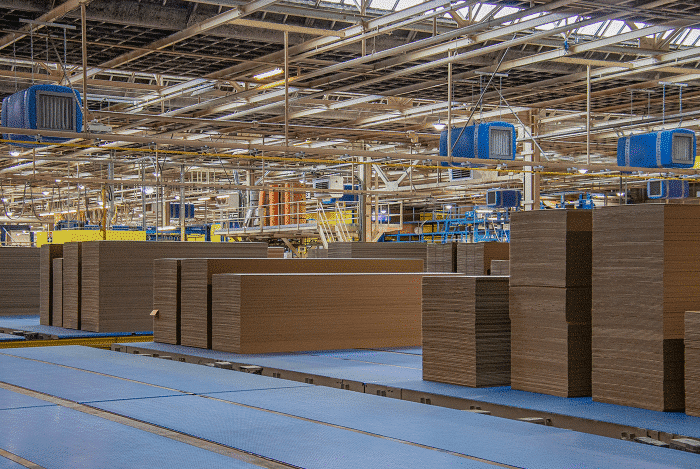

Tilburg is home to the industrial heavy-duty packaging division. This involves corrugated packaging of extremely heavy quality in large formats, which generally holds heavy weights. The octabins, which are used for transporting granulate, next to that packaging is made for high-end bicycles and various applications in the automotive industry.

About 220 people work at the Tilburg site and the total business area is over 55 000m2. In October 2023, the heavy-duty division will be 60 years old. Safety and staff welfare are high priorities at DS Smith. For example, at the time of the reference visit in Tilburg, there have already been 2909 days without an industrial accident requiring absenteeism.