Improving Air Quality in Industry

The developments in the industry are moving at lightning speed. Innovation, sustainability and global trends and developments play an important role. Air pollution in industrial buildings is a major problem, be it metalworking, logistics, woodworking or the paper industry. Fine dust particles, metal fumes, oil mist, wood dust and gases are created during the work. This includes boxes that slide over each other and forklift tires that wear out due to intensive use.

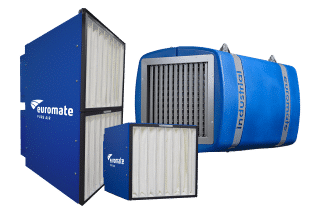

Building-related systems provide sufficient fresh air, but cannot absorb the pollution. Euromate’s professional air cleaners can be strategically placed in areas where the most pollution is generated. The units provide a dust reduction of up to 90%. An additional advantage is that the air flows are optimized; this ensures a pleasant temperature all year round.

References in Industry

Holland Packing

Klingele Paper and Packing

Phoenix Pallets B.V.

Plastic Recycling Company

Welkoop Retail

Chep

Bilfinger Noell GmbH

Products for the Industrial Branche

HF-Series Industrial air cleaners

- Filters up to 90% of the contamination

- Suitable for industrial environments

- Customized solution for different pollution sources

DFI-Series industrial air cleaners

- Ensures dust reduction of up to 90%

- customised solution based on dust concentration

- Suitable for warehouses, industrial and logistic halls

Air Quality Sensors

- Measures PM 10, PM 2,5, PM 1, CO2, temperature and humidity

- Always real-time insight into your air quality

- Periodic reports and alerts available