With a team of forty knowledgeable and capable machining specialists, Timmermans Verspaningstechniek is capable of producing just about any workpiece to the most detailed of requirements. Timmermans Verspaningstechniek BV was established in Oudenbosch in 1989 and has grown considerably since its foundation.

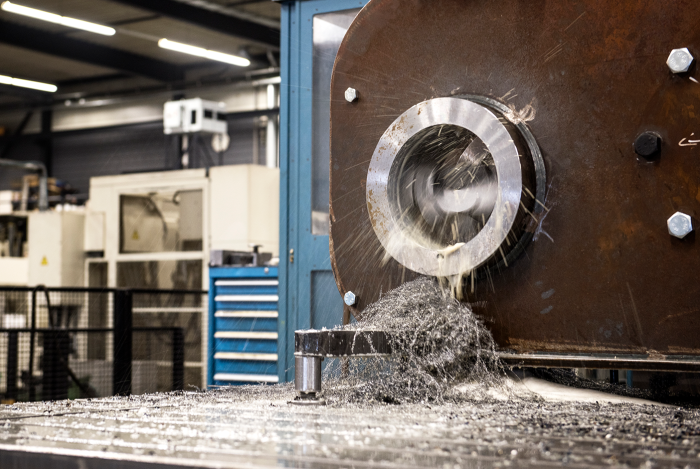

Timmermans Verspaningstechniek has more than 25 years of expertise and experience in machining technology and has amassed an impressive fleet of machinery. The company employs a combination of technologies including boring, turning, milling, drilling, surface grinding, sawing and welding to produce products for its customers. The company’s employees, machinery and tools are all part of an operation that revolves around safe, sustainable and efficient production.