In 2007, the product range was expanded to include the production of windows and façades. “Since 2008, we’ve also been a window manufacturer,” says Ludger Wittland. At that time, Josef Terhalle already had 80 employees in his own company. He took over his former training company located directly adjacent to his property along with all 30 employees.

“Today, we produce everything ourselves that relates to the closed building envelope,” Wittland explains. “We have our own joiners, carpenters and roofers, which means the envelope is complete. For all technical building systems, we collaborate with specialized partners.”

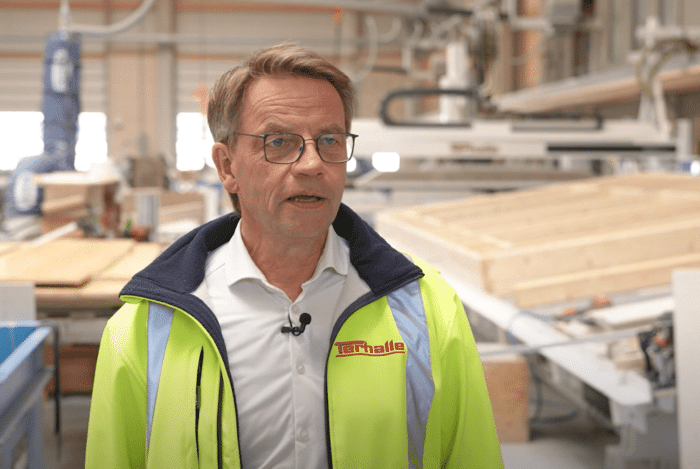

Through acquisitions and expansions, the Terhalle Group now also includes a metal construction company, a roofing company, an architectural office, and branches in Berlin and Hengelo (the Netherlands). “I’ve been with the company for ten years now, and every year we’ve built a new hall,” says Wittland. A company in constant growth, now employing more than 620 people, all proud of their successful organization.